Product Description

Perforated boxes from Rigid Packaging are special boxes with small, evenly spaced holes or cuts in them. Think of it like a connect the dots picture, but instead of drawing lines, you’re tearing along a line that’s already there. These little holes make it super easy to tear the box open or remove parts of it. This is really useful in many different situations.

What are Perforated Boxes Used For?

Imagine you buy a box of cookies. With a regular box, you have to fumble around trying to open it neatly. Sometimes you rip the box, and it looks messy. With a perforated box, you can just gently tear along the pre cut line. You get a nice, clean opening every time. This makes it easy to grab a cookie and makes the box look presentable.

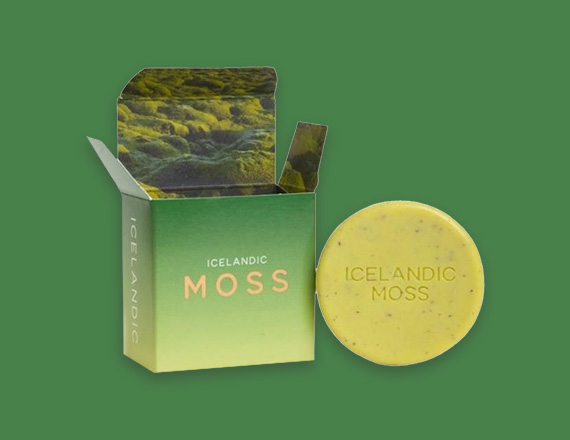

Another use is for displaying products in stores. Say you have a box of small toys. The box can sit on a shelf with the front panel easily torn away along the perforations. This shows off the toys inside without having to completely unpack the entire box. It saves the store workers time and makes the product look more appealing to customers.

Perforated boxes are also great for mailing things. If you’re sending a package that needs to be opened easily, perforations make it simple for the receiver to access the contents. No need to search for scissors or a knife. This is especially helpful for subscription boxes where people are excited to see what’s inside.

Benefits of Using Perforated Boxes

The biggest benefit is easy opening. This is a huge advantage for both the person packing the box and the person opening it. It saves time and frustration. Everyone likes things that are easy to use.

Another benefit is neatness. When you tear along the perforations, you get a clean, straight line. This looks much better than a jagged, ripped edge. This is important if you want your product to look professional.

Perforated boxes can also reduce waste. Sometimes, when people struggle to open a box, they end up damaging the product inside. With easy opening, there’s less chance of damaging the contents, which means less waste.

For businesses, using perforated boxes can improve customer satisfaction. Customers appreciate packaging that is easy to open and doesn’t require extra tools. Happy customers are more likely to buy from you again.

Types of Perforation

There are different types of perforations. Some perforations are made with small, close together holes. These are easy to tear. Other perforations have larger holes or spaces between the holes. These are stronger and require more force to tear.

The type of perforation used depends on the material of the box and what it will be used for. A box that needs to be opened easily will have smaller, closer perforations. A box that needs to be more durable will have larger or more spaced out perforations.

The size and spacing of the perforations can also be customized to fit your specific needs. Rigid Packaging can help you choose the right type of perforation for your product.

Materials Used for Perforated Boxes

Perforated boxes can be made from different materials. Cardboard is a popular choice because it is strong and affordable. Corrugated cardboard, which has a wavy layer inside, is even stronger and is often used for shipping heavier items.

Paperboard is another option. It is thinner than cardboard and is often used for packaging food or smaller items. Plastic can also be used for perforated boxes, especially for items that need to be protected from moisture.

The material you choose will depend on the weight of your product, how much protection it needs, and your budget. Rigid Packaging offers a variety of materials to choose from.

Why Choose Rigid Packaging for Your Perforated Boxes?

Rigid Packaging has a lot of experience making high quality perforated boxes. We use the latest technology to create precise perforations that are easy to tear and look great. We can customize the size, shape, and material of your boxes to meet your specific needs.

We offer a wide range of options, from simple cardboard boxes to more complex designs with custom printing. We can print your logo and other information on the boxes to help you promote your brand.

We are committed to providing excellent customer service. Our team will work with you every step of the way to ensure you get the perfect boxes for your product. We offer competitive pricing and fast turnaround times.

If you are looking for a reliable supplier of perforated boxes, look no further than Rigid Packaging. Contact us today to learn more about our products and services. We are confident that we can provide you with the best perforated boxes for your needs.

Our turnaround time is 8-10 working days. You may shop with us for as low as just 100 pieces. Moreover, your design customizations will be taken care of by our expert designers. You can consult with them to have the most amazing designs for your

Industry. Our customer service is available 24/7. You can contact us via live chat, send us an email at

sales@rigidpackaging.co.uk or simply call at +44 736 2028015 for instant assistance.